Porcelain paving has transformed modern gardens. It offers crisp lines, colour stability, minimal maintenance and exceptional strength — when it is properly made.

However, one uncomfortable truth is rarely explained: two porcelains can look identical on the surface, yet perform completely differently once installed outdoors.

In this guide we explore:

This is not a brand endorsement or a sales pitch. It is an engineering and materials guide, written from hands-on experience in real UK gardens.

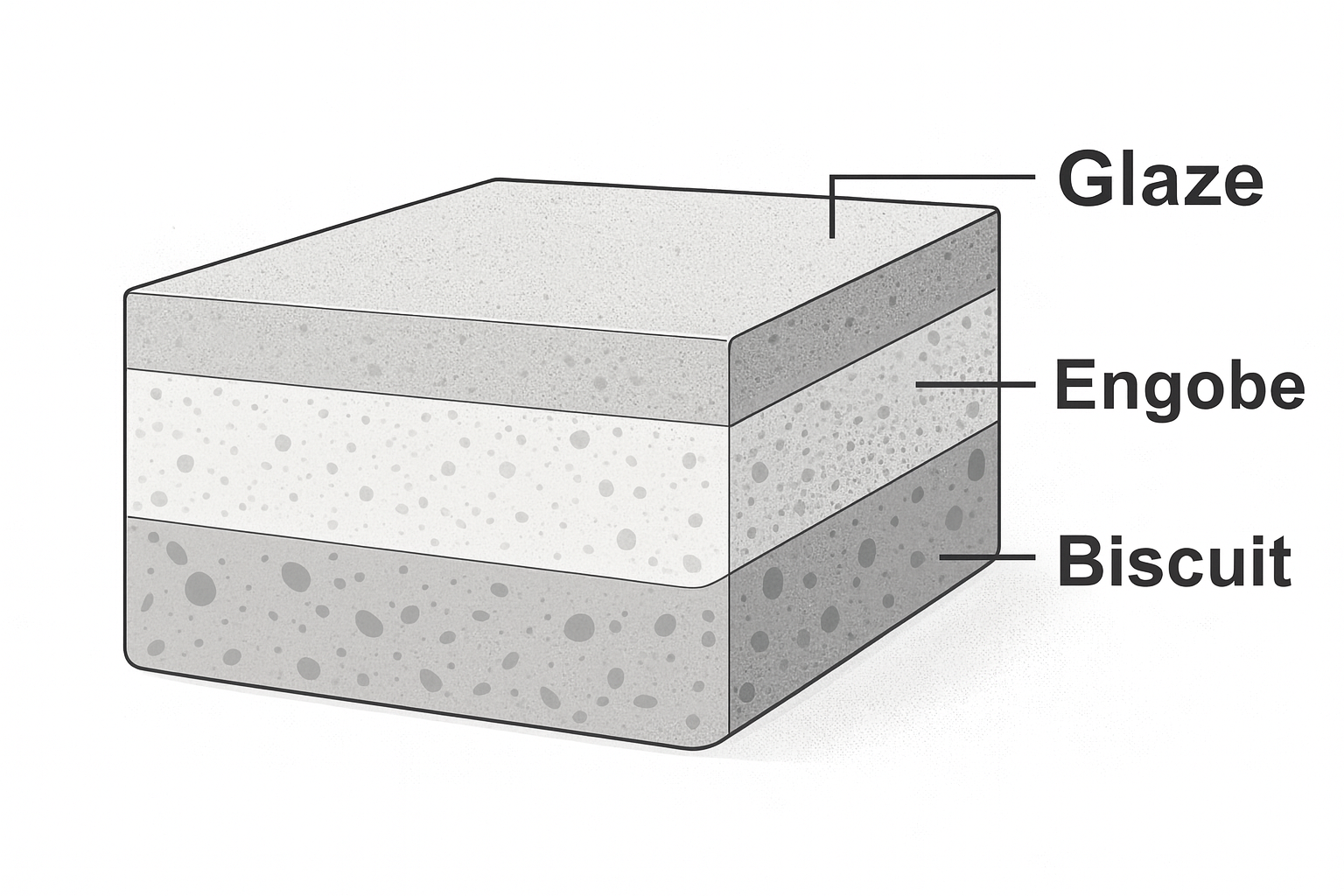

Porcelain is not stone, concrete, or ceramic in the casual sense. It is a high-density, vitrified ceramic made from carefully selected minerals and fired at extreme temperatures.

True porcelain is defined by:

When made correctly, porcelain is one of the most durable paving materials available for UK gardens. When made poorly, it simply looks like porcelain — and behaves very differently.

Good porcelain begins long before a tile is pressed or fired. Quality is built in at every stage.

Premium porcelain uses refined:

Impurities such as excess iron, organic matter or uncontrolled recycled fillers are tightly managed. This consistency matters because porcelain’s strength comes from what happens inside the body, not on the surface print.

Materials are milled into a very fine slurry and then spray-dried into uniform granules. This stage determines:

Poor control here leads to density variations that cannot be fixed later.

The granulated material is pressed into moulds under enormous pressure. In high-quality production:

This uniformity is essential for outdoor paving, where point loads and minor movement are unavoidable.

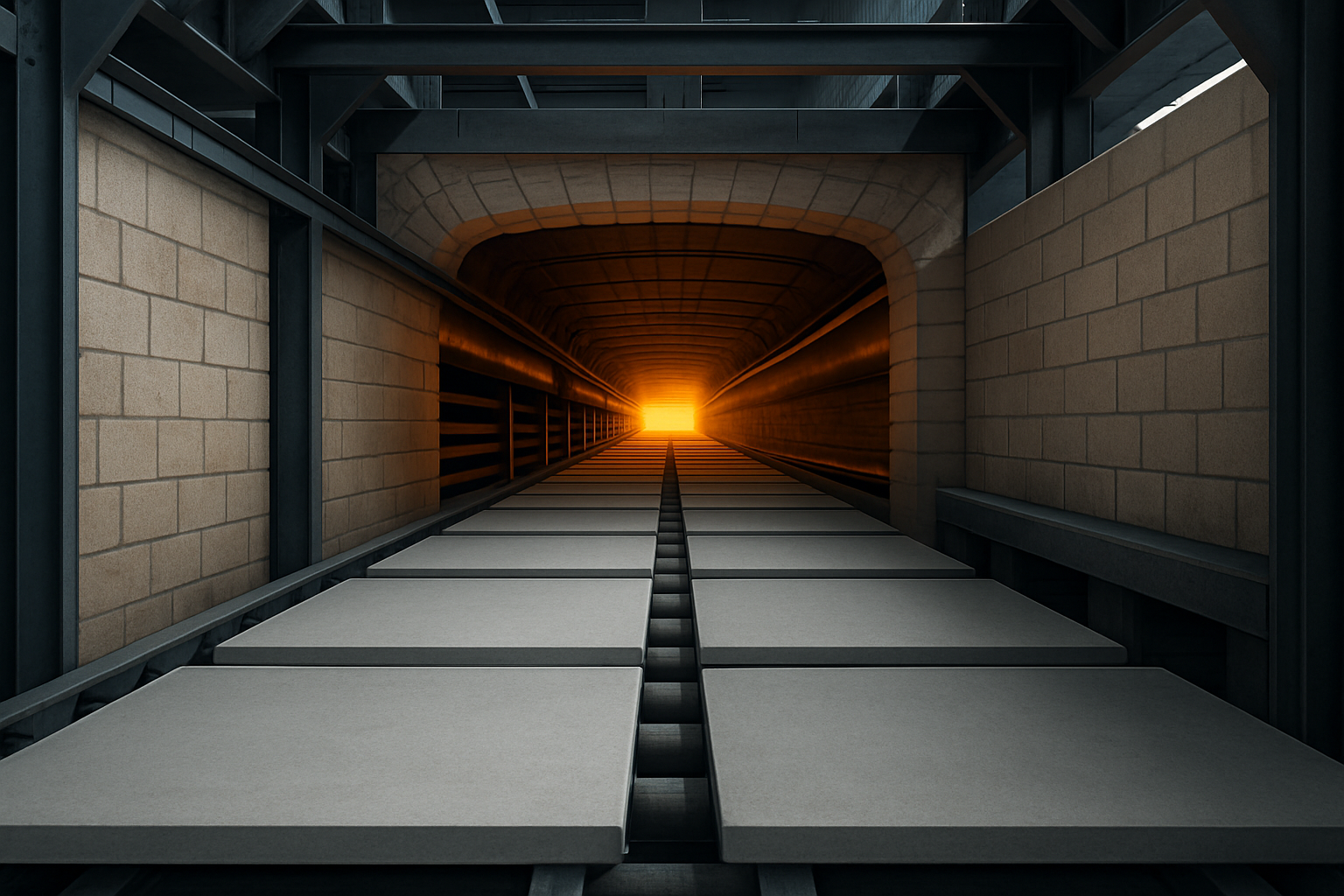

This is the most critical stage. High-quality porcelain is fired:

During firing:

This is what gives premium porcelain its frost resistance, strength and long service life.

After firing, good manufacturers:

Many tiles never leave the factory. This rejection rate is one reason high-quality porcelain costs more.

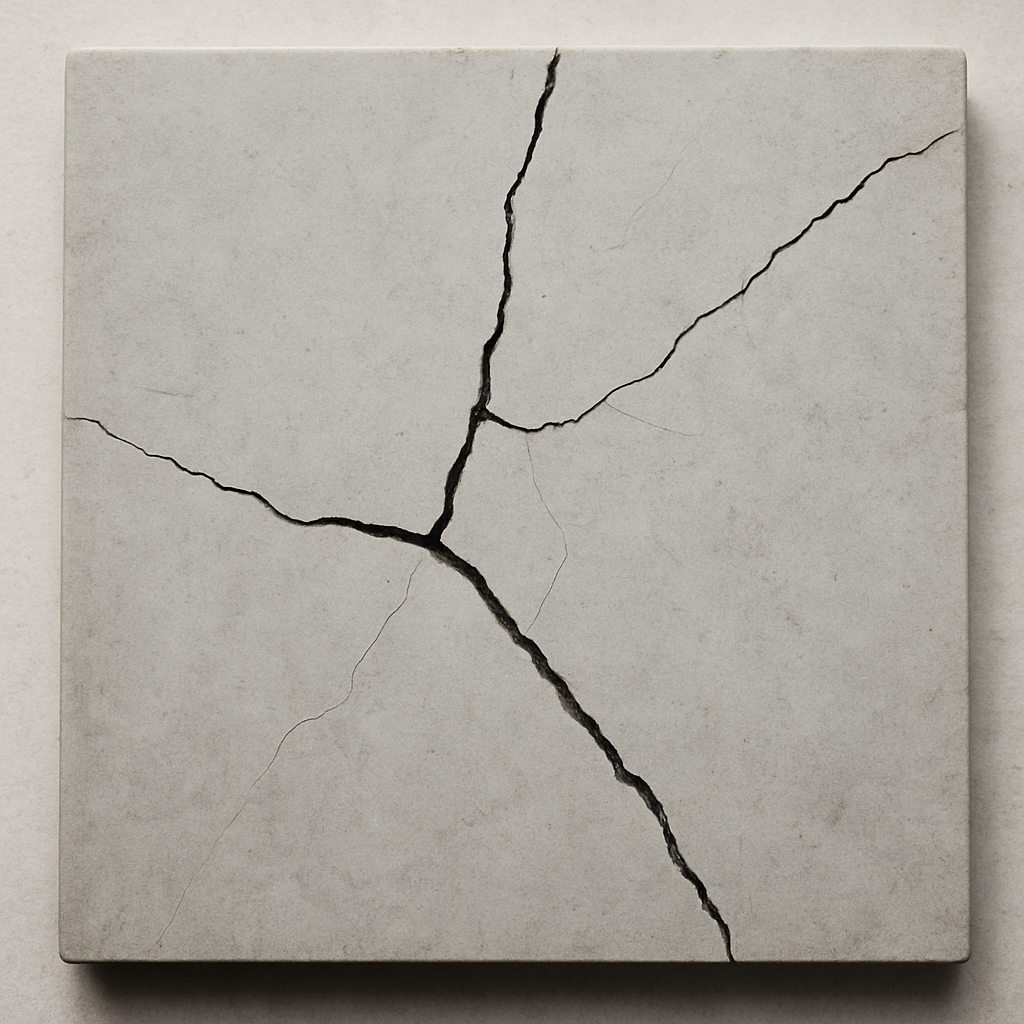

Some porcelain products reach the market having technically passed minimum standards — yet fall short where it matters outdoors. The most common issues arise from shortcuts, not accidents.

Energy is expensive. Shorter, cooler kiln cycles save money — but leave:

Such tiles absorb stress instead of distributing it.

Lower-grade presses or rushed cycles lead to:

These failures often appear months after installation, once gardens experience real weather and use.

Some factories introduce:

This increases variability and reduces mechanical integrity — particularly at edges and corners.

Poor rectification can leave sharp, brittle edges that become stress concentrators, especially when:

UK gardens are demanding environments:

Outdoor paving does not fail in perfect conditions — it fails at the margins. Well-made porcelain tolerates these margins. Poorly made porcelain does not. Cracking is rarely dramatic or immediate. It often begins invisibly, inside the slab.

This is not about fashion or nationalism. It is about manufacturing discipline. Many premium porcelain producers are based around Sassuolo in Italy, a region with decades of ceramic engineering expertise.

Characteristics consistently seen in high-end Italian porcelain include:

The result is porcelain that behaves as a single, solid body rather than a fragile surface over a compromised core.

Clients who are exploring the very top end of porcelain paving often like to research the origins of the materials they choose. For reference, some long-established manufacturers with strong reputations in the design and architectural world include:

Sitting between commodity imports and these specialist Italian factories is a group of familiar paving brands that many UK homeowners will recognise. Well-established names such as Marshalls, Global Stone and Ca’ Pietra offer porcelain ranges that are widely used in British gardens and are often backed by multi-year guarantees. Those guarantees do not make a tile indestructible, but they usually indicate a reasonable level of testing, technical support and batch control behind the product.

Links are provided for information only. We specify products on a project-by-project basis, taking into account suitability, availability and budget.

No. There is no universal crest or label that guarantees excellence. Standards such as CE marking and EN classifications confirm that a tile meets minimum requirements — not that it excels.

True quality becomes evident through:

This is where experience matters.

At The Landscape Company, porcelain is never chosen solely on appearance. Before we agree to install a product, we consider:

We do not use porcelain that relies on perfect conditions to survive.

Where relevant, we may link to manufacturer or supplier websites for reference purposes only, allowing clients to explore production methods or technical details directly from the source. These links are informational, not endorsements.

Porcelain paving can be one of the most durable, low-maintenance and visually refined materials for a garden — when it is properly made and correctly installed.

The difference between a porcelain patio that lasts decades and one that develops problems is rarely visible at first glance. It lies in engineering, process, discipline and respect for the material. That difference matters.

If you are considering a new porcelain terrace or want a second opinion on materials that have been suggested for your project, we are happy to share practical advice based on real installations.

Call: 01428 654812 · 07500 877949

Email: richard@tlchaslemere.co.uk

WhatsApp: Send a WhatsApp message

Telegram: Message on Telegram